Outboard boat propellers have seen steady advancements in recent years, with manufacturers focusing on improving performance, durability, and fuel efficiency. Modern propellers feature refined blade geometries designed through computational fluid dynamics (CFD) simulations. These new blade shapes often incorporate progressive pitch, cupping, or variable thickness profiles. Such designs optimize water flow over the blades, enhancing thrust, acceleration, and handling stability across a range of engine RPMs. Multi-blade propellers—especially 4- and 5-blade models—are also gaining popularity for their ability to improve low-speed control and reduce cavitation.

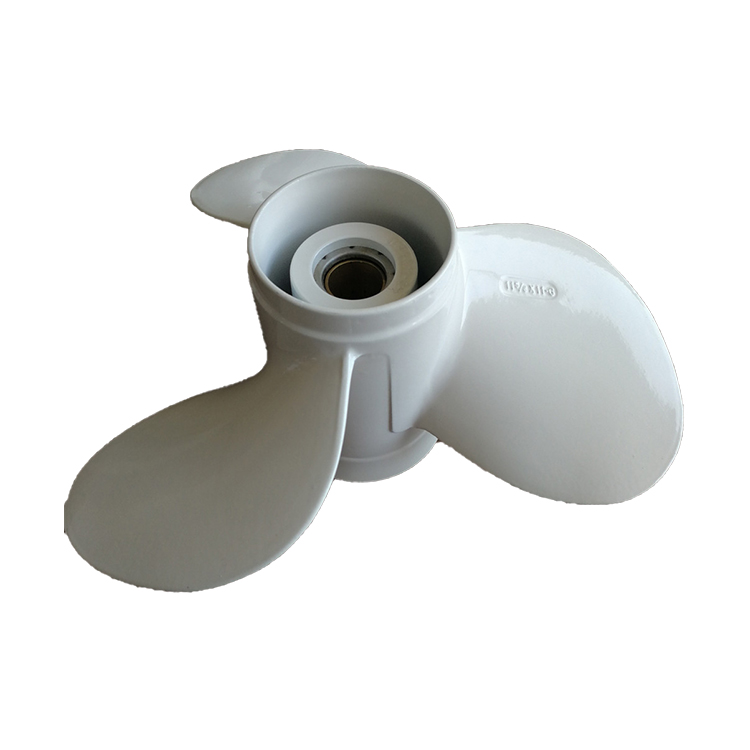

While aluminum and stainless steel remain the primary materials, newer models include composite blades or hybrid construction, which combine metal hubs with replaceable polymer blades. These designs aim to balance affordability with durability and ease of maintenance. Some advanced polymers used in these props offer corrosion resistance and reduce vibration, making them suitable for smaller boats and electric outboard motors.

Newer outboard propellers often use modular or interchangeable hub systems, such as Mercury's Flo-Torq or Yamaha's SDS (Shift Dampener System). These systems allow boaters to switch propellers between different engines or applications without the need for additional hardware. They also reduce gear case shock and enable smoother shifting.

Advances in manufacturing—such as CNC-machined props and tighter production tolerances—result in more balanced, efficient, and consistent propeller performance. These improvements help reduce engine load and increase overall propulsion efficiency.

Stainless steel boat propellers are widely regarded as a premium option in the boating industry. Known for their strength and durability, they are preferred by many boaters who prioritize performance, reliability, and long-term value over initial cost savings.

Stainless steel is significantly stronger than aluminum and composite materials. This higher strength allows for thinner, more precisely shaped blades that can cut through water more efficiently. Because of their structural integrity, stainless steel props are better suited for high-speed applications and boats operating in demanding conditions such as shallow or debris-prone waters. They are less likely to deform, crack, or chip when encountering obstacles, extending the service life of the propeller.

Due to their rigidity, stainless steel propellers maintain their shape under load, which directly translates to consistent thrust and better responsiveness. Boaters often notice improved acceleration, top-end speed, and fuel economy when switching to stainless steel props. The enhanced blade design options also allow for fine-tuning the pitch and diameter, enabling boaters to match the propeller more precisely to the boat's performance requirements.

Stainless steel contains chromium, which provides a natural resistance to corrosion, especially in saltwater environments. While regular maintenance is still necessary, stainless steel props require less frequent replacement compared to aluminum models, particularly for boats stored in or frequently used on saltwater.

Thanks to their weight and precision, stainless steel propellers contribute to smoother handling and improved load-carrying performance. Boats equipped with stainless steel props tend to plane faster and maintain speed more efficiently under load.

While stainless steel propellers generally come at a higher upfront cost, their long-term reliability and performance benefits often justify the investment, especially for frequent boaters or those who operate in varied or challenging waters.