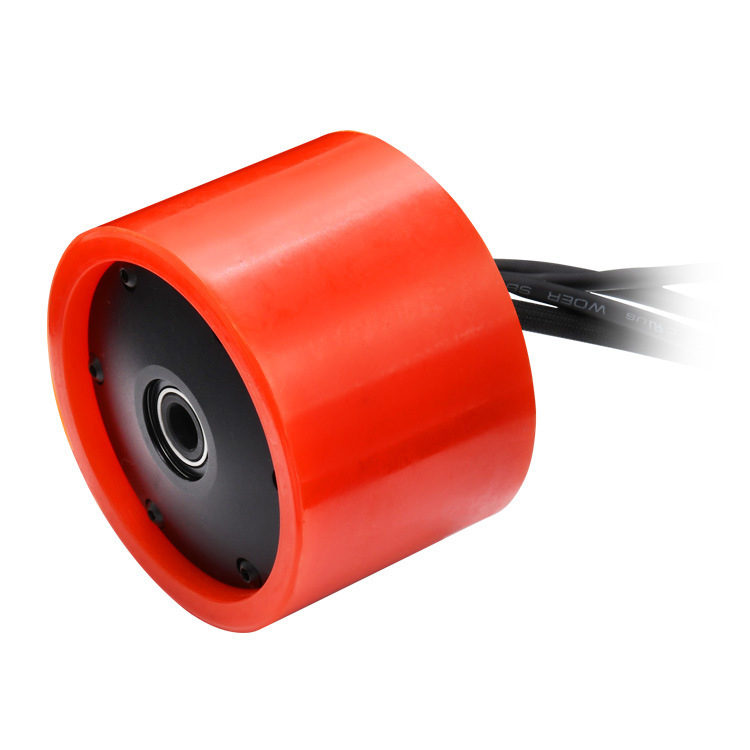

As electric skateboards evolve to deliver faster, smoother, and more reliable performance, the sensored brushless high RPM gear motor for electric skateboard applications has become an increasingly preferred choice among engineers and advanced riders. This type of motor offers a combination of precise low-speed control, high-speed capability, and efficient power transfer through gearing. However, as with any high-performance system, the sensored brushless high RPM gear motor for electric skateboard applications brings its own set of engineering and practical challenges.

One of the foremost challenges in using a sensored brushless high RPM gear motor for electric skateboard platforms is thermal regulation. These motors are designed to operate at high revolutions per minute, often exceeding 10,000 RPM, which inherently generates more heat. The gear reduction mechanism, while improving torque output, also introduces friction losses that contribute to the thermal load.

When a sensored brushless high RPM gear motor for electric skateboard operates continuously under demanding conditions—such as hill climbs or heavy acceleration—the internal temperature can rise quickly. Without adequate cooling solutions, such as heat sinks or air ventilation paths, the motor's magnets and winding insulation can degrade over time, reduced performance or premature failure.

The "sensored" component of a sensored brushless high RPM gear motor for electric skateboard refers to the use of Hall effect sensors or encoders to monitor rotor position. These sensors enable smooth starts, precise throttle control, and effective regenerative braking. However, sensor alignment must be finely calibrated.

In a sensored brushless high RPM gear motor for electric skateboard, incorrect sensor positioning can cause timing errors, cogging at low speeds or jerky acceleration. Environmental conditions such as vibration, water exposure, or dust ingress may also impact sensor accuracy, especially when the motor is not fully sealed. Thus, ensuring the sensors remain stable and protected in real-world skateboard use is critical to maintaining performance.

While the addition of a gear mechanism helps convert high motor RPMs into usable torque for wheel rotation, the inclusion of mechanical components introduces concerns over long-term durability. A sensored brushless high RPM gear motor for electric skateboard with metal or polymer gears must be engineered to resist wear from repeated use, road impacts, and sudden load changes.

High-speed rotation and gear engagement naturally produce vibration and acoustic noise. For an electric skateboard, where riders are directly in contact with the motor mount and deck, this can translate to a less comfortable ride. Managing vibration in a sensored brushless high RPM gear motor for electric skateboard involves fine-tuning motor balance, implementing rubber isolation mounts, and ensuring precise machining of the gear teeth.

If vibration is not properly managed, it may also affect the sensor's long-term accuracy, degraded control and motor efficiency. Therefore, it is important to consider structural reinforcement and dampening when designing a sensored brushless high RPM gear motor for electric skateboard system.

The performance of a sensored brushless high RPM gear motor for electric skateboard heavily depends on how well it integrates with the ESC. The ESC must be capable of interpreting sensor data and managing rapid current changes without delay. Poorly matched ESCs can result in delayed throttle response, inefficient power delivery, or overheating.

Additionally, a sensored brushless high RPM gear motor for electric skateboard must be tuned through firmware parameters such as timing advance, acceleration curves, and braking force to match the rider's expectations and the skateboard's mechanical configuration. Incorrect settings can strain both the motor and the ESC.