As modern electronic devices continue to become more compact, functional, and visually appealing, display technology has had to evolve accordingly. Among the innovations gaining popularity across consumer electronics, wearables, and industrial applications is the Small Round Display Module LCD Screen. Unlike traditional square or rectangular displays, these circular modules offer a unique aesthetic and efficient use of space, especially in devices where space and design harmony are crucial. But what exactly goes into designing a Small Round Display Module LCD Screen, and what technical aspects determine its functionality and performance?

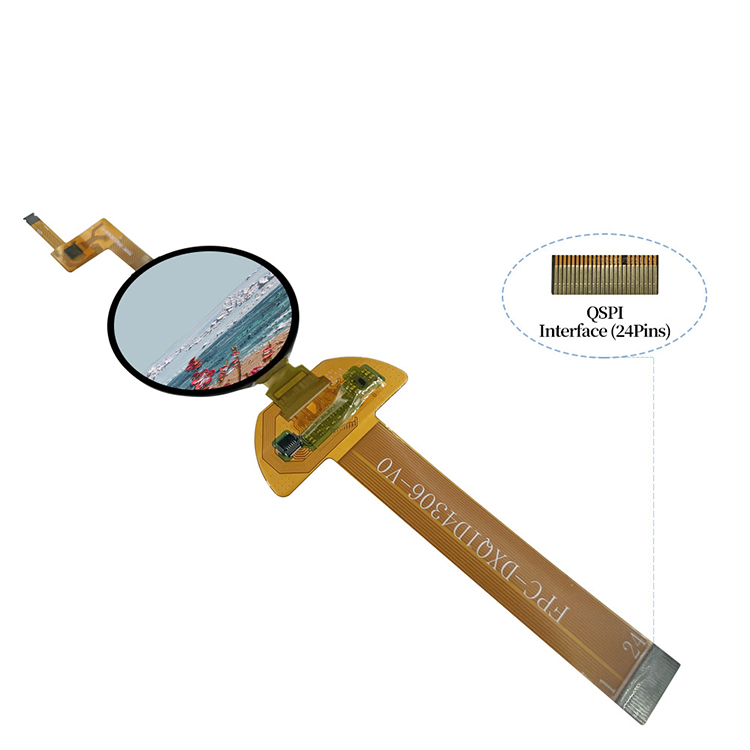

A Small Round Display Module LCD Screen is a circular-shaped liquid crystal display designed for use in compact devices, often measuring between 0.96 inches and 2.1 inches in diameter. These modules integrate the display panel with necessary drivers and interface circuitry, making them easy to incorporate into embedded systems.

Commonly seen in smartwatches, fitness trackers, medical devices, instrument panels, and even home appliances, the Small Round Display Module LCD Screen offers both form and function. The round shape is particularly valued for applications requiring symmetry or where traditional display shapes do not optimize the product's visual layout.

Every Small Round Display Module LCD Screen consists of several critical elements:

LCD Panel: The core of the screen, usually based on TFT (Thin Film Transistor) technology, responsible for pixel control and display quality.

Backlight Unit (BLU): Typically LED-based, this layer ensures uniform illumination behind the LCD panel.

Polarizers: These help control light direction, enabling visibility under various lighting conditions.

Driver IC: An integrated circuit that translates image data into signals that control the screen pixels.

Touch Panel (optional): Many Small Round Display Module LCD Screen units incorporate capacitive or resistive touch layers for interactivity.

Flexible or Rigid PCB: Provides electrical connectivity and sometimes includes embedded interface controllers (SPI, I2C, etc.).

These components are tightly integrated within a compact footprint, allowing for seamless embedding in small electronic devices.

The manufacturing of a Small Round Display Module LCD Screen requires precision and consistency due to the compact size and curved geometry. Unlike rectangular displays, round modules involve a more complex cutting process from a larger glass substrate. This adds complexity to both production and quality control.

During the TFT fabrication phase, transistors are layered onto a glass substrate using photolithographic techniques. For Small Round Display Module LCD Screen production, manufacturers employ laser or precision diamond-cutting equipment to shape the panels. The backlight and driver IC are then laminated onto the panel, followed by polarizer films and the optional touch layer.

Special attention is given to alignment and sealing, ensuring that the circular geometry does not interfere with optical performance or uneven backlighting. The resulting module is tested for brightness, contrast, viewing angle, touch sensitivity, and color accuracy.

There are several criteria that influence the quality and usability of a Small Round Display Module LCD Screen:

Resolution and Pixel Density: Higher resolutions offer sharper images, especially important for wearable applications where the screen is close to the user's eye.

Brightness and Contrast: Essential for readability under varying lighting conditions, including outdoor use.

Response Time: Fast response improves usability in interactive applications like touch displays or animations.

Viewing Angle: In a Small Round Display Module LCD Screen, a wide viewing angle ensures consistent visuals across the curved edges.

Power Efficiency: Devices using these screens often rely on small batteries, so optimizing power draw is essential.

Touch Accuracy and Sensitivity: If touch-enabled, the screen must offer precise response without latency.