The Electric Vehicle Controller is essentially the brain that governs how the electric motor behaves in response to user inputs and system feedback. It interprets data from various sensors, such as accelerator position, battery voltage, motor temperature, and braking signals, and then sends the appropriate commands to the motor and other subsystems. Without a properly designed Electric Vehicle Controller, even the most advanced drivetrain can become ineffective or unstable.

At its core, the functional design of the Electric Vehicle Controller must strike a balance between performance, energy efficiency, and safety. From a manufacturer's standpoint, this involves not just the hardware itself but also the embedded software algorithms. These algorithms need to be responsive, fault-tolerant, and capable of real-time decision-making based on rapidly changing conditions on the road.

One of the primary responsibilities of the Electric Vehicle Controller is to regulate motor torque output. It must translate the driver's input into precise control signals while taking into account road incline, load, and battery status. Smooth acceleration and deceleration are vital not only for driving comfort but also for energy conservation and component longevity. For this reason, the controller's design must incorporate reliable power electronics and efficient signal processing.

Another critical function of the Electric Vehicle Controller is thermal management. During operation, components such as the inverter and motor generate significant heat. The controller monitors temperature readings and adjusts power flow to prevent overheating. If unsafe conditions are detected, the controller may initiate protective actions such as power reduction or complete motor shutdown. This protective logic is integrated into both the hardware safety circuits and the firmware.

From a manufacturing perspective, interoperability is also a key consideration. The Electric Vehicle Controller needs to communicate with other modules in the vehicle — including the Battery Management System (BMS), charging unit, and dashboard interface. This requires adherence to communication standards like CAN bus or LIN protocols. Ensuring that the controller can seamlessly exchange data with various systems reduces integration challenges during vehicle assembly.

Scalability is another aspect that influences how manufacturers approach the design of the Electric Vehicle Controller. Given the wide range of vehicle classes — from two-wheelers and compact cars to commercial transport vehicles — it's often necessary to develop controller platforms that can be configured or scaled based on application requirements. A modular design approach enables faster adaptation and reduces production costs across different product lines.

Additionally, the Electric Vehicle Controller must support regenerative braking, a feature where kinetic energy is converted back into electrical energy during braking and sent to the battery. The controller must manage this process carefully to avoid overcharging the battery or causing instability during vehicle deceleration. This requires close coordination with both the braking system and the BMS.

Software updates and diagnostics are also part of a modern Electric Vehicle Controller’s responsibilities. As vehicles become more connected, over-the-air updates are becoming a standard feature. Manufacturers need to ensure that the controller hardware supports firmware flashing and can securely authenticate and implement software changes. Diagnostic capabilities help identify issues during production testing as well as throughout the vehicle’s lifespan.

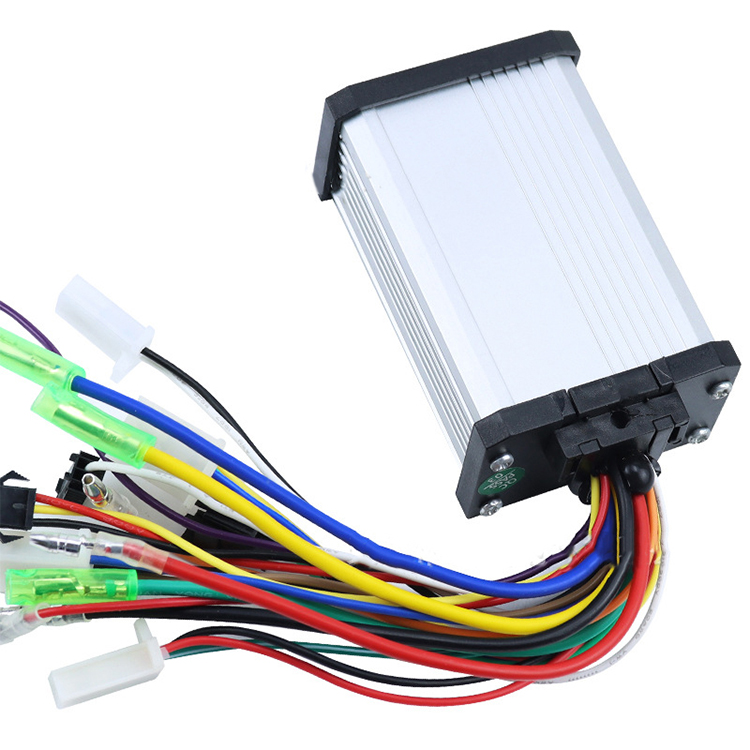

Reliability and testing play a major role in the manufacturing process. Each Electric Vehicle Controller undergoes a series of validation steps to ensure it can perform under a range of operating conditions. This includes testing for electromagnetic compatibility, vibration tolerance, temperature variation, and water/dust resistance. Controllers used in outdoor or high-vibration environments are often enclosed in sealed casings to protect sensitive electronics.

Finally, cost-efficiency and material selection cannot be ignored. While performance remains the priority, manufacturers must also consider the choice of processors, capacitors, and other electronic components to maintain affordability without sacrificing durability or functionality. Designing a competitive Electric Vehicle Controller involves sourcing reliable components and assembling them with precision.