The transition to electric mobility is more than just batteries and motors; it's a complex interplay of advanced electronics that bring a vehicle to life. At the heart of this system lies a component often described as the "brain" of the electric car: the Electric Vehicle Controller. This crucial device is responsible for managing the flow of electrical energy from the battery to the motor, translating the driver's commands into precise motion. But not all controllers are created equal. The choices made in their design and configuration have a direct impact on a vehicle's performance, efficiency, and driving character. For engineers, enthusiasts, and prospective buyers, understanding the landscape of controller options—from their fundamental architectural designs to their software capabilities—provides a deeper appreciation of the technology powering the future of transport.

Architectural Design: Centralized vs. Distributed Systems

One of the primary considerations in vehicle design is the physical and functional architecture of the control system. This dictates how the various control units are organized within the vehicle.

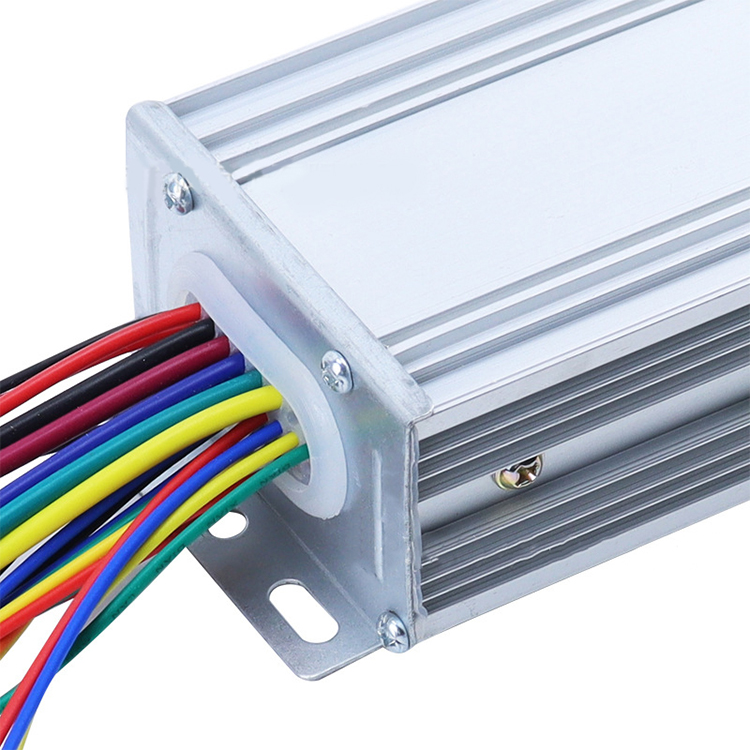

Centralized Controller Architecture: In this approach, a single, powerful Electric Vehicle Controller or a small number of domain controllers manage multiple functions. For instance, one central unit might handle both the powertrain (motor and transmission) and the regenerative braking system. This architecture can simplify wiring harnesses, reduce the overall number of components, and potentially lower costs. It allows for consolidated processing, which can be beneficial for complex coordination between systems.

Distributed Controller Architecture: This traditional model uses a network of dedicated electronic control units (ECUs), each responsible for a specific subsystem. In this setup, a dedicated Electric Vehicle Controller manages the motor, while separate ECUs control the battery management system, thermal management, and charging. This design offers modularity, making it easier to troubleshoot and replace individual components. It also allows for greater flexibility, as different suppliers can provide specialized controllers for different functions.

The choice between these architectures often depends on the vehicle manufacturer's philosophy, the desired balance between integration and modularity, and the complexity of the vehicle platform.

Power Electronics and Semiconductor Technology

The core of any controller is its power electronics—the components that physically switch the high currents required by the motor. The technology used here is a key differentiator in terms of efficiency, size, and cost.

Insulated-Gate Bipolar Transistors (IGBTs): For many years, IGBTs have been the workhorse of power electronics in traction inverters, which are a core part of the Electric Vehicle Controller. They are robust, cost-effective for high-power applications, and well-suited for the voltage and current levels found in many EVs. They are a reliable choice, particularly in vehicles where peak performance is prioritized over efficiency in all driving conditions.

Silicon Carbide (SiC) MOSFETs: A significant technological shift is underway with the adoption of wide-bandgap semiconductors like Silicon Carbide. SiC-based controllers offer higher efficiency, especially at partial loads, which is common in everyday city driving. They can operate at higher switching frequencies and temperatures, which can a smaller and lighter Electric Vehicle Controller and a corresponding reduction in the size of associated cooling systems. While often having a higher initial cost, SiC technology can contribute to greater overall vehicle range.

Gallium Nitride (GaN): As an emerging technology, GaN offers potential benefits beyond even SiC, particularly for high-frequency applications. While currently more common in lower-power applications like onboard chargers, its evolution may influence future generations of motor controllers, pushing the boundaries of power density and efficiency further.

Performance Calibration and Software Features

The hardware is only one part of the equation; the software and calibration that run on the Electric Vehicle Controller define the vehicle's driving dynamics and user experience.

Driving Modes: Modern controllers are defined by their software, which allows for multiple driving modes (e.g., Eco, Normal, Sport). These modes alter the controller's parameters, changing the throttle response curve, the power output limit, and the aggressiveness of regenerative braking. This software-based flexibility allows a single vehicle to offer a range of driving characters.

Torque Vectoring and Advanced Stability Control: Sophisticated controllers can manage power delivery not just to a single motor, but individually to motors on the left and right wheels (e.g., on a rear axle). This capability, known as torque vectoring, can significantly enhance handling and stability by actively applying torque to specific wheels to help steer the car through a corner or maintain grip.