An AC motor controller for electric vehicles is an electronic device that regulates the operation of the vehicle's alternating current (AC) motor. It converts the direct current (DC) stored in the battery into alternating current through an inverter circuit, and precisely controls the frequency and amplitude of this AC power to drive the motor at different speeds and torque levels. This component serves as the central interface between the driver's input (via accelerator or brake pedals) and the motor's behavior on the road.

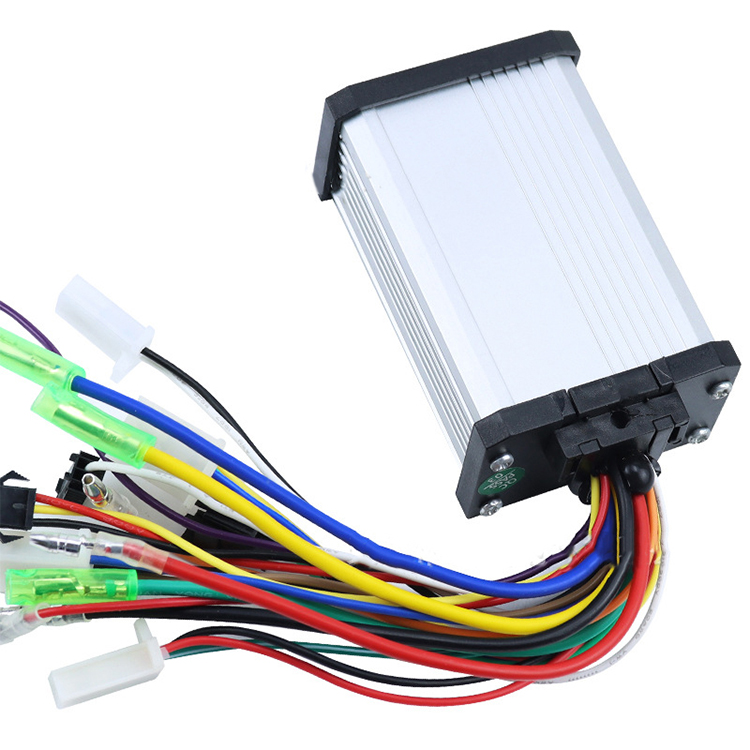

Typically, an AC motor controller for electric vehicles includes three core subsystems: the inverter, the control logic, and the power stage. The inverter converts the DC power into a three-phase AC waveform suitable for driving AC induction or permanent magnet synchronous motors (PMSMs). The control logic interprets signals from the driver and from onboard sensors, adjusting parameters like motor speed, direction, and torque. Finally, the power stage, composed of insulated gate bipolar transistors (IGBTs) or MOSFETs, physically handles the switching and distribution of power to the motor windings.

The AC motor controller for electric vehicles also plays a key role in energy regeneration. During braking or deceleration, it switches the motor to generator mode, sending recovered energy back to the battery. Moreover, modern controllers are equipped with thermal management features, fault detection protocols, and communication interfaces such as CAN bus to ensure safe and efficient operation.

In a modern electric vehicle, the car electronic control module (ECM) refers to any embedded system that monitors or manages an electrical subsystem. These modules are essential to both vehicle performance and safety. They function as compact computers, programmed with software to handle specific operations such as motor control, battery management, braking systems, infotainment, and climate control.

One of the main technical features of a car electronic control module is real-time signal processing. ECMs collect input from sensors—such as temperature, pressure, speed, and position sensors—and use microcontrollers to process this data in milliseconds. Based on programmed algorithms, the ECM then sends output commands to actuators and other modules to ensure appropriate vehicle responses. For example, the ECM that handles traction control will adjust motor torque in response to wheel slip detected by speed sensors.

Another vital characteristic is network communication capability. Many car electronic control modules communicate through in-vehicle networks such as CAN (Controller Area Network), LIN (Local Interconnect Network), or FlexRay, allowing different modules to share information. This architecture ensures that the braking system, motor controller, battery management system (BMS), and other units operate in a synchronized manner.

Durability and environmental resistance are also critical. ECMs are designed to function in a wide range of temperatures, vibrations, and moisture levels. They are sealed to prevent dust and water ingress and undergo rigorous testing to meet automotive safety and reliability standards.

Lastly, diagnostic and update functions are integrated into ECM. They can detect and log system errors, making troubleshooting easier for technicians. Increasingly, these modules also support over-the-air (OTA) software updates, allowing manufacturers to improve vehicle functionality post-sale.

Car electronic control modules are the digital backbone of an EV, ensuring that various complex systems work together efficiently, safely, and adaptively under all driving conditions.